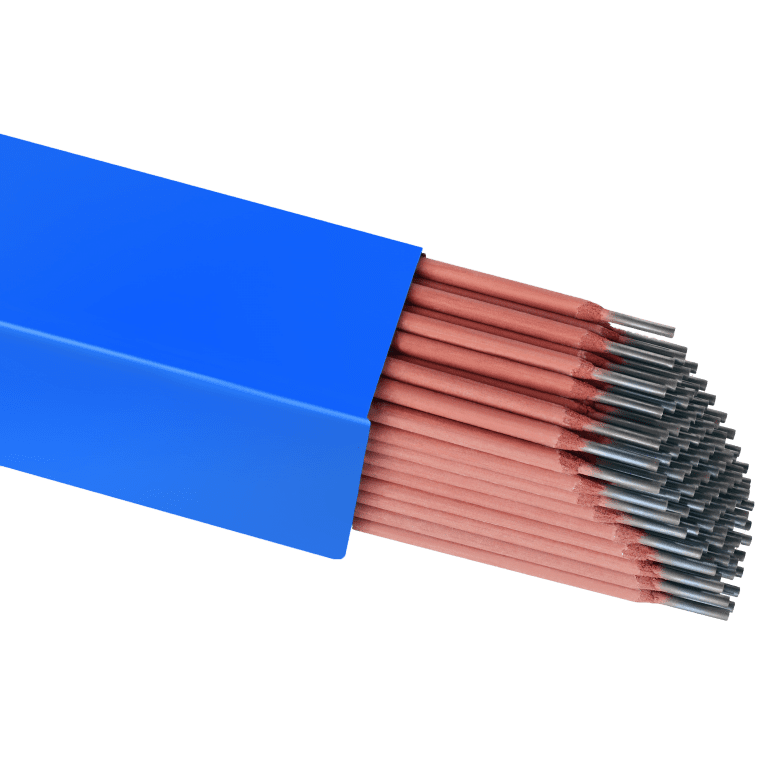

Welding

Iron Powder is used as a coating material in stick electrodes and as filler material in flux-cored wires. It improves the yield and efficiency of electrodes. It is most commonly used in low hydrogen type electrodes (E7018).

A small addition to all types of stick electrodes generally improves weld metal recovery. Stable chemistry, uniform particle size distribution and low impurities are critical to the quality of Iron powders.

Good quality Iron Powder helps in a smoother arc with less splatter.

SLM provides superior quality Sponge and Atomized Iron Powders for welding applications.

Different Grade Specifications

-

ATOMISED IRON POWDER

- SPONGE IRON POWDER

AIP 40.29

Low oxygen Atomised Iron powder for Welding Applications

AD – 3.00 gm/cc

Fe – 99% min

Oxygen: 0.20% max

SLM 40.29

AD – 2.95 gm/cc

Fe – 98%

40 Mesh Powder

SLM 40.37

AD – 3.75 gm/cc

Fe – 98%

40 Mesh Powder

SLM 100.25