SLM Metal Powders for

Chemical and Metallurgical applications

SLM Metal has a wide range of metal powders specifically produced for chemical and metallurgical applications from the production of welding rods to body warmers.

For over three decades, SLM has established itself as a trusted provider of top-notch metal powder products, setting a benchmark for excellence worldwide. With an extensive customer base spanning across more than 20 countries, SLM possesses an in-depth understanding of the evolving needs of the rapidly expanding global industry.

From Atomised Iron Powders to Sponge Iron Powders and beyond, SLM specialises in the precise manufacturing and curation of exceptional quality metal powders. These powders are engineered to meet the rigorous demands of a wide range of industrial applications.

SLM metal powders are pioneers in recycling of scrap metal and producing high quality metal powders which are quality tested and approved for industrial as well as pharmaceutical usage.

In metallurgy, iron powder plays a crucial role in various processes and applications due to its unique properties. Some common uses of iron powder in metallurgy include:

Sintering

Iron powder is a fundamental material used in the sintering process. Sintering involves compacting iron powder into specific shapes and then heating it below its melting point. This process helps create solid objects with enhanced strength and density, making it valuable for manufacturing complex components and parts.

Alloying

Iron powder is often used as an alloying element in the production of steel and other metal alloys. By adding metal powder to the mix, the properties of the resulting alloy can be adjusted to meet specific requirements, such as improved strength, hardness, and corrosion resistance.

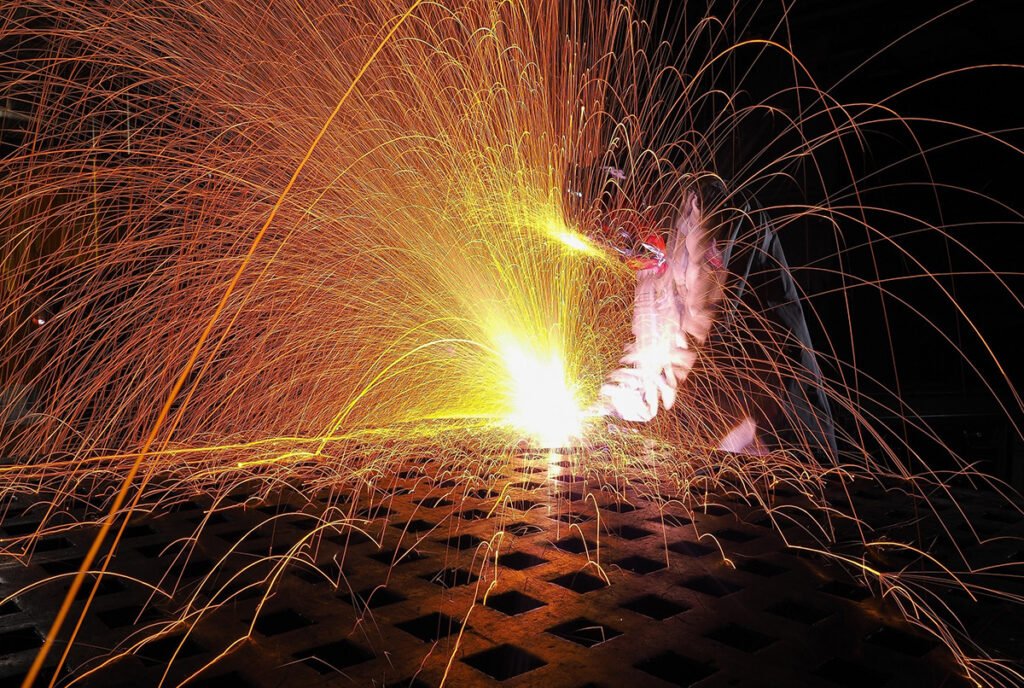

Brazing and Welding

Iron powder is utilised in brazing and welding processes, where it acts as a filler material to join metal parts together. The powder is mixed with a binding agent and applied to the joint, and upon heating, it melts, fusing the components.

Powder Metallurgy

As mentioned earlier, iron powder is a key component in the powder metallurgy process, which involves compacting and sintering metal powders to create various products, such as gears, bearings, bushings, and structural components.

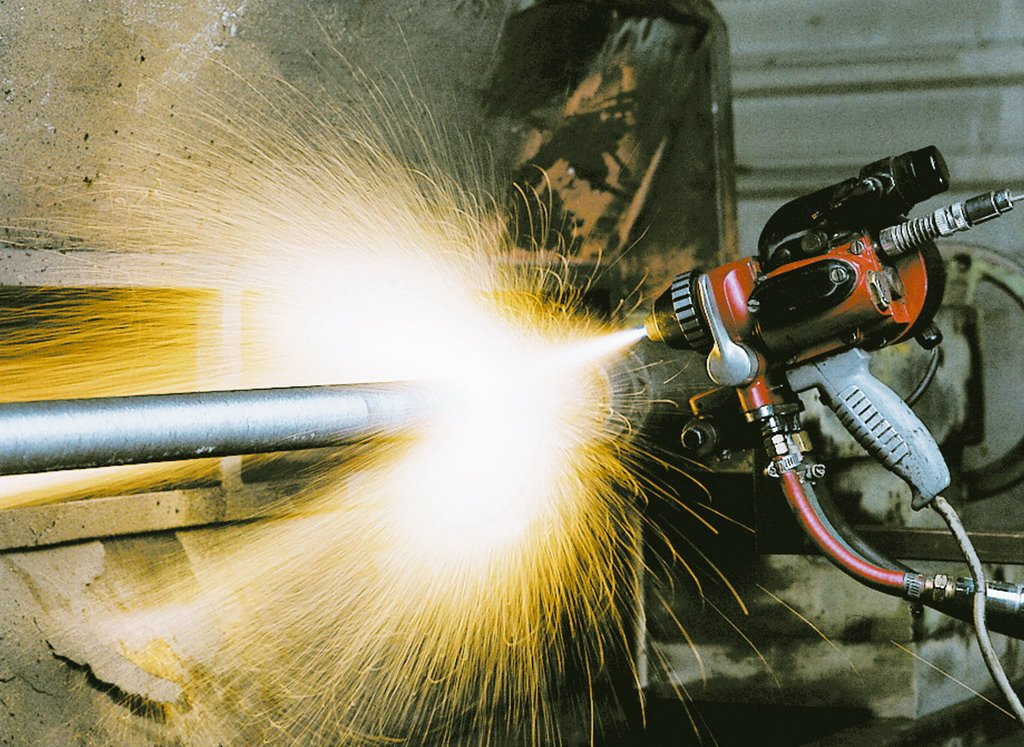

Thermal Spraying

Iron powder is used in thermal spraying techniques, where it is heated and propelled onto a surface to create a protective or functional coating. This process is applied to improve wear resistance, reduce corrosion, and restore damaged or worn-out parts.

Additive Manufacturing

Iron powder is utilised in metal additive manufacturing processes, commonly known as 3D printing, to create intricate metal parts with high precision and complexity.

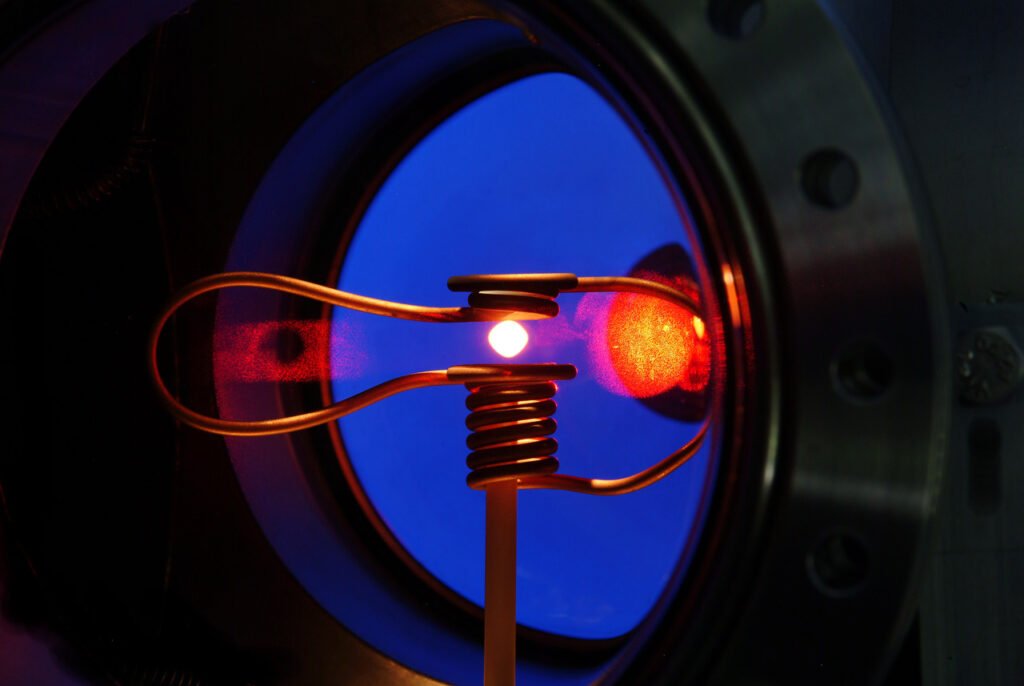

Soft Magnetic Applications

Iron powder is employed to produce soft magnetic materials used in applications like electromagnetic coils, magnetic cores for transformers, inductors, and motors.

Metal Injection Molding

Iron powder is a critical component in MIM, a process that combines powder metallurgy and injection moulding techniques to produce complex metal parts with tight tolerances.

Iron Powder Cores

Iron powder is used in the manufacturing of magnetic cores for inductors, chokes, and transformers, especially in applications requiring high-frequency performance.

Overall, iron powder’s versatility and ability to be combined with other metals make it an essential material in various metallurgical processes, contributing significantly to the production of a wide range of metal products used in industries worldwide.

It’s important to note that the specific grade and characteristics of iron powder may vary depending on the intended application. Additionally, safety precautions should be taken while handling iron powder, especially fine particles, to avoid inhalation and skin contact.

Features and benefits of SLM Metal powders:

- Optimization of powders for the specific purpose of the applications.

- Widest range of powders having different apparent densities, particle sizes, surface areas, purities and morphologies to suit your specific needs.

- Cost-effective and tailor-made solutions.

- Mixing solutions on request.

SLM Metal Private Limited

SLM Technology Private Limited

Uditnagar, Rourkela – 769012,

Odisha, India.