The demand for efficient and high-quality welding processes has led to continuous advancements in welding consumables. Cored wires, a popular choice among welders, have gained significant attention due to their enhanced performance and versatility. Among the various components used in cored wires, iron powder stands out as a crucial ingredient. In this article, we will explore the benefits of iron powder usage in cored wires, the different types available, applications across industries, selection considerations, handling and storage guidelines, safety precautions, and future trends in this field.

1. Introduction

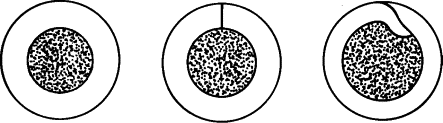

Welding plays a vital role in various industries, including automotive, construction, shipbuilding, and many others. Cored wires, also known as flux-cored wires, are composite welding consumables that consist of a metal sheath filled with a flux compound. This unique design allows for efficient and controlled deposition of weld metal, providing excellent weld quality and productivity.

2. What is Iron Powder?

Iron powder is a finely powdered form of iron metal, produced through different processes such as atomization, reduction, or electrolysis. The powder’s particle size and purity can vary based on the manufacturing method. Iron powder offers distinct advantages when used as an additive in cored wires, making it an indispensable component in modern welding applications.

3. Benefits of Iron Powder in Cored Wires

Improved Welding Performance

The inclusion of iron powder in cored wires improves the overall welding performance. Iron has a high melting point and excellent thermal conductivity, allowing for better heat distribution during the welding process. This results in reduced spatter, improved arc stability, and enhanced control over the weld pool, leading to high-quality welds.

Enhanced Mechanical Properties

The addition of iron powder in cored wires contributes to the refinement of the weld metal’s microstructure. This refinement leads to improved mechanical properties such as tensile strength, impact resistance, and ductility. Weldments produced with iron powder cored wires exhibit superior toughness and are better able to withstand dynamic loading conditions.

Increased Deposition Rate

Iron powder cored wires offer a higher deposition rate compared to traditional solid wires. The presence of iron powder allows for a higher metal transfer rate, resulting in increased productivity and faster welding speeds. This is particularly advantageous for applications that require high-volume welding, such as large-scale fabrication projects.

4. Types of Iron Powder Used in Cored Wires

There are different types of iron powder used in the production of cored wires, each with its specific characteristics and applications. The three commonly used types are:

Atomized Iron Powder

Atomized iron powder is produced by spraying molten iron into a chamber where it solidifies into small spherical particles. This type of iron powder offers excellent flowability and produces weld deposits with high density and low porosity. It is widely used in cored wires for general-purpose welding applications.

Reduced Iron Powder

Reduced iron powder is manufactured through the reduction of iron oxide. It has a more irregular particle shape compared to atomized iron powder. Reduced iron powder provides good arc stability and is suitable for welding applications that require high penetration and high deposition rates.

Electrolytic Iron Powder

Electrolytic iron powder is produced by electrolysis, resulting in a high-purity iron powder with controlled particle size distribution. It offers excellent arc stability, low spatter, and high deposition efficiency. Electrolytic iron powder is commonly used in specialized welding applications, including those that require precise control over alloy composition.

5. Applications of Cored Wires with Iron Powder

The usage of iron powder in cored wires extends to various industries and welding applications. Some key areas where cored wires with iron powder find extensive use include:

Welding and Fabrication

In welding and fabrication, cored wires with iron powder are employed for a wide range of applications, including structural steel welding, pipe welding, and repair work. The enhanced weld quality and productivity offered by these wires make them a preferred choice for professional welders.

Automotive Industry

The automotive industry relies heavily on cored wires with iron powder for welding various components, such as chassis, exhaust systems, and body panels. The high deposition rates and improved mechanical properties contribute to the production of strong and durable welds in automobile manufacturing.

Construction Sector

Cored wires with iron powder play a crucial role in the construction sector, where welding is essential for joining structural elements, building infrastructure, and repairing machinery. The high deposition rates and improved control over the welding process make these wires ideal for construction applications.

Shipbuilding and Marine Industry

Shipbuilding and the marine industry demand reliable and high-quality welding solutions. Cored wires with iron powder offer excellent weldability and mechanical properties, making them suitable for shipbuilding, offshore construction, and repair of marine vessels.

6. Choosing the Right Iron Powder for Cored Wires

When selecting cored wires with iron powder, several factors should be considered to ensure optimal performance:

Wire Diameter and Flux Composition

The diameter of the cored wire and the composition of the flux should be selected based on the specific welding application and the desired weld characteristics. It is important to match the wire diameter and flux composition with the welding process and base metal to achieve the desired results.

Welding Conditions and Base Metal

The welding conditions, including the welding current, voltage, and travel speed, along with the characteristics of the base metal, influence the selection of iron powder cored wires. It is essential to choose wires that are compatible with the welding conditions and base metal to achieve optimal weld quality and mechanical properties.

Quality and Certification

When purchasing cored wires with iron powder, it is crucial to consider the quality and certification standards. Look for wires that meet industry-recognized specifications and have appropriate certifications to ensure reliability and performance.

7. Handling and Storage of Iron Powder Cored Wires

Proper handling and storage of iron powder cored wires are essential to maintain their quality and prevent any degradation. Consider the following guidelines:

Moisture Control

Iron powder is susceptible to moisture absorption, which can lead to rusting and reduced weld quality. Ensure that cored wires are stored in a dry environment with controlled humidity levels. Use moisture-resistant packaging or containers to protect the wires from moisture ingress.

Temperature and Humidity Considerations

Avoid exposing iron powder cored wires to extreme temperatures and humidity. High temperatures can cause the flux to degrade, while excessive humidity can result in moisture absorption. Maintain a suitable storage environment with moderate temperature and humidity levels.

Proper Packaging and Handling

Cored wires should be stored in their original packaging or in sealed containers to prevent contamination and moisture exposure. Handle the wires with care, avoiding any physical damage that may affect their performance.

8. Safety Considerations when Using Iron Powder Cored Wires

Safety should be a priority when working with iron powder cored wires. Consider the following precautions:

Dust Control Measures

Iron powder can generate fine particles during handling and welding operations. Implement dust control measures, such as using local exhaust ventilation and dust collection systems, to minimize exposure to airborne particles. Regularly clean the work area and use appropriate cleaning methods to control dust accumulation.

Personal Protective Equipment (PPE)

Wear appropriate personal protective equipment when working with iron powder cored wires. This may include safety glasses, gloves, protective clothing, and respiratory protection, such as a dust mask or respirator, to prevent inhalation of airborne particles.

Proper Ventilation

Ensure adequate ventilation in the welding area to remove fumes and airborne particles generated during welding. Good ventilation helps maintain a safe and healthy work environment.

9. Future Trends and Innovations in Iron Powder Cored Wires

The field of iron powder cored wires is continuously evolving, with ongoing research and development to enhance their performance and expand their applications. Future trends may include:

- Development of new alloy compositions for specialized welding applications.

- Improvements in wire feeding technology for better control and efficiency.

- Advancements in flux formulations to further enhance weld quality and properties.

- Integration of automation and robotics for efficient and precise welding processes.

10. Conclusion

Iron powder usage in cored wires brings numerous benefits to welding processes. With improved welding performance, enhanced mechanical properties, and increased deposition rates, cored wires with iron powder offer a reliable solution for a wide range of applications in industries such as automotive, construction, and shipbuilding. By selecting the right type of iron powder and adhering to proper handling, storage, and safety practices, welders can achieve high-quality welds and maximize productivity. As the industry continues to innovate, the future holds exciting possibilities for further advancements in iron powder cored wires.

11. FAQs

Q: What is the shelf life of iron powder cored wires?

A: The shelf life of iron powder cored wires can vary depending on the manufacturer and storage conditions. It is recommended to refer to the manufacturer’s guidelines for specific information regarding shelf life and storage recommendations.

Q: Can iron powder cored wires be used for stainless steel welding?

A: Yes, iron powder cored wires can be used for stainless steel welding. However, it is important to choose wires specifically designed for stainless steel applications to ensure optimal results and avoid potential issues such as excessive carbon pickup.

Q: Are there any environmental concerns related to iron powder usage in cored wires?

A: Iron powder usage in cored wires is generally considered safe and environmentally friendly. However, it is essential to follow proper handling and disposal practices to minimize any potential environmental impact. This includes proper containment of dust and waste materials, as well as compliance with local regulations for the disposal of used cored wires and associated packaging.

Q: Can iron powder cored wires be used with different welding processes?

A: Yes, iron powder cored wires can be used with various welding processes, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). However, it is important to select the appropriate wire type and welding parameters for each specific process to achieve optimal results.

Q: How does iron powder improve the stability of the arc during welding?

A: Iron powder’s high melting point and thermal conductivity contribute to improved arc stability during welding. The presence of iron powder in cored wires helps to regulate the heat distribution and control the molten metal pool, resulting in a stable and controlled arc throughout the welding process.

Q: Can iron powder cored wires be used for automated welding applications?

A: Yes, iron powder cored wires are suitable for automated welding applications. Their high deposition rates and consistent weld quality make them compatible with robotic and automated welding systems, enhancing productivity and efficiency in industrial settings.

Q: What are the advantages of using iron powder cored wires over solid wires?

A: Iron powder cored wires offer several advantages over solid wires. They provide higher deposition rates, improved control over the welding process, enhanced mechanical properties, and reduced spatter. Additionally, cored wires with iron powder are often more cost-effective and can improve welding productivity.