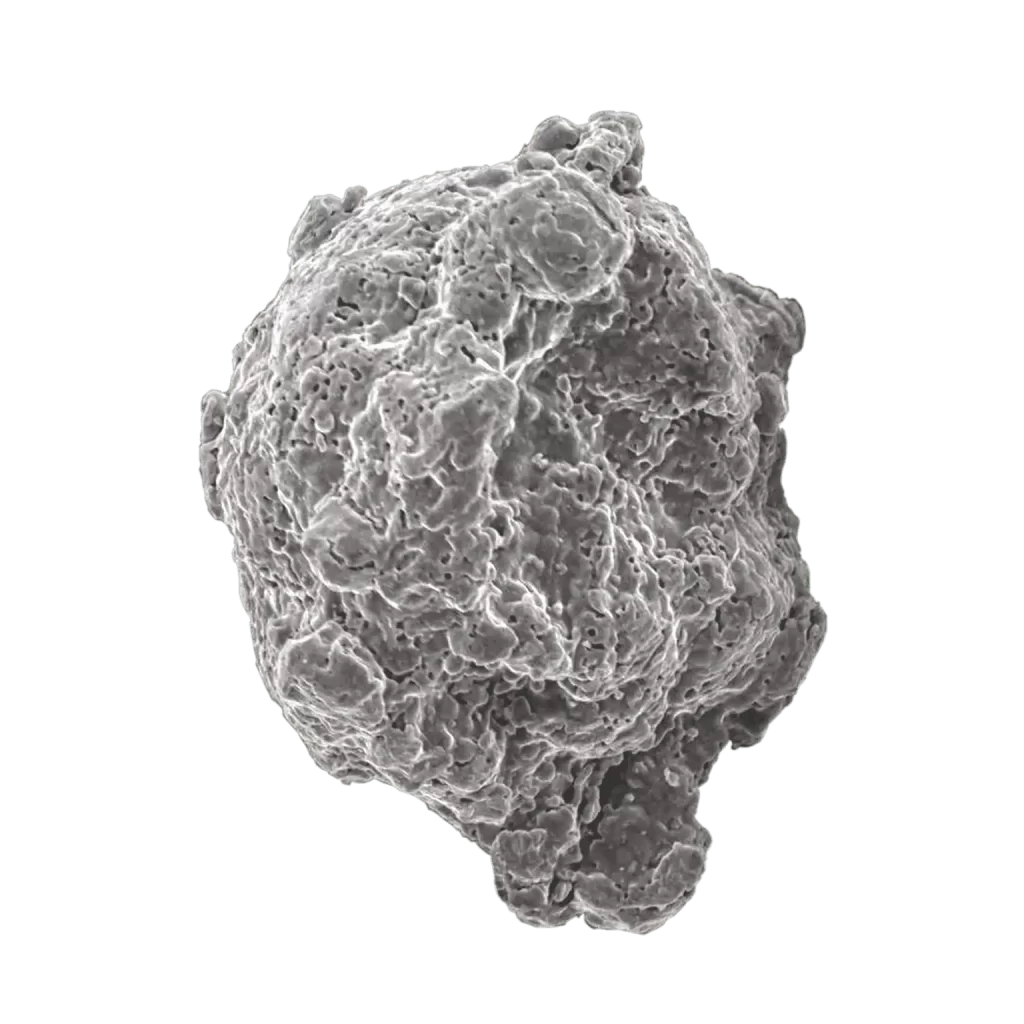

Atomised Iron Powder

For high-density sintered parts, our water-atomized iron powders are most suitable. A variety of grades of water atomized iron powders are available, and customisable as per application requirements.

Different Grade Specifications

-

POWDER METALLURGY

- WELDING

- FRICTION

- ALUMINIUM ALLOYING

- CORED WIRES

Atomised Iron Powder for structural parts offering consistent dimensional change properties after sintering.

Contact us for Technical data sheet

AD – 2.95 gm/cc

GD – 7.10 gm/cc

100 Mesh Powder

High compressibility atomised iron powder suitable for higher density parts.

Contact us for Technical data sheet

AD – 2.95 gm/cc

GD – 7.16 gm/cc

100 Mesh Powder

Low density Atomised Iron Powder for low density parts like shock absorber pistons.

AD – 2.65 gm/cc

GD – 7.08 gm/cc

GS – 30 MPa*

*600 MPa die-wall

Low density Atomised Iron Powder offering high green strength to the parts with thin edges or lugs.

AD – 2.95 gm/cc

GD – 7.10 gm/cc

GS – 44 MPa *

*600 MPa die-wall

Low oxygen Atomised Iron powder for Welding Applications

AD – 3.00 gm/cc

Fe – 99% min

Oxygen: 0.20% max

Low density Atomised Iron Powder with high surface area and high green strength ideal for clutch and brake pads.

AD – 2.45gm/cc

GD – 7.0 gm/cc

100 Mesh Powder

Atomised Iron Powder used for adding iron into molten aluminium for foil applications.

AD - 3.00 gm/cc

Fe – 99% min

40 mesh powder

High density Iron Powder used in metallurgical Cored Wire along with other additives like calcium etc.

AD – 3.30 gm/cc

20 mesh powder

AD – 3.30 gm/cc

40 mesh powder

Properties of our Water Atomized Iron Powder

SLM’s water-atomized iron powder offers a set of properties that make it highly desirable for sintered component manufacturing:

High Compressibility – Enables the production of dense parts with enhanced mechanical strength.

Excellent Flowability – Ensures uniform filling of molds, leading to precise and consistent part geometries.

Superior Sinterability – Enhances bonding between particles, resulting in high-strength final products.

Controlled Particle Size Distribution – Customizable for different applications such as structural components, filtration media, and friction materials.

Low Oxygen Content – Improves the mechanical and magnetic properties of the finished products.

For more information reach us out.