Particle Size Matters: Iron Powder Selection Guide

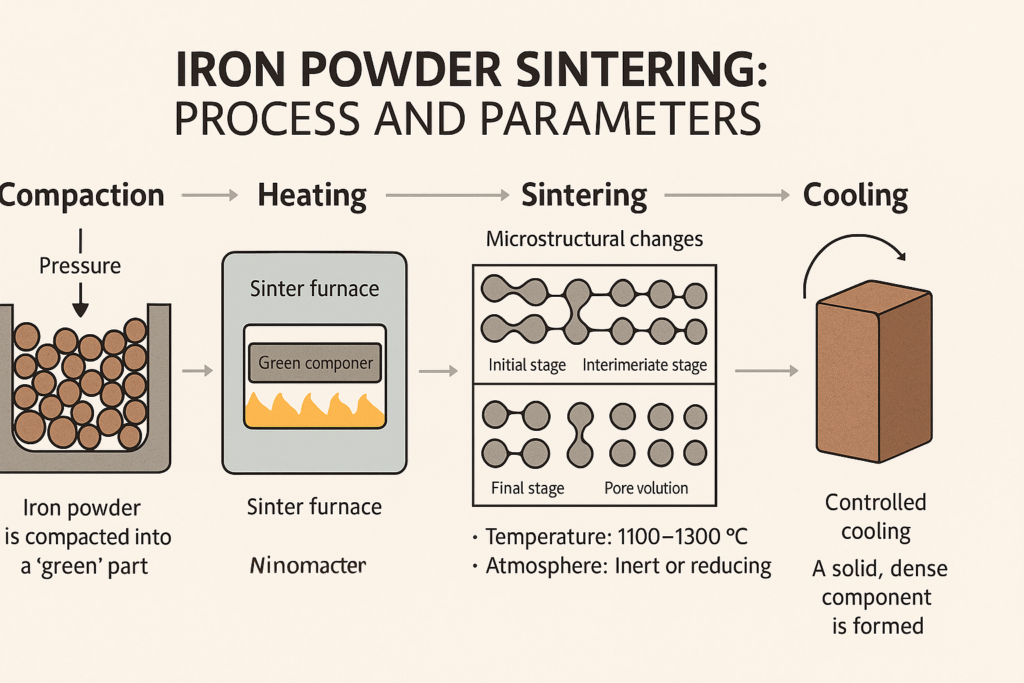

Find out why particle size is crucial in choosing iron powder for various uses In the world of iron powder applications, one factor silently governs everything from flowability to sintering behavior and final part performance—particle size. Whether you’re producing automotive parts through powder metallurgy or formulating welding electrodes, the size and distribution of iron powder […]

Particle Size Matters: Iron Powder Selection Guide Read More »